[CRAIG NIGRELLI]

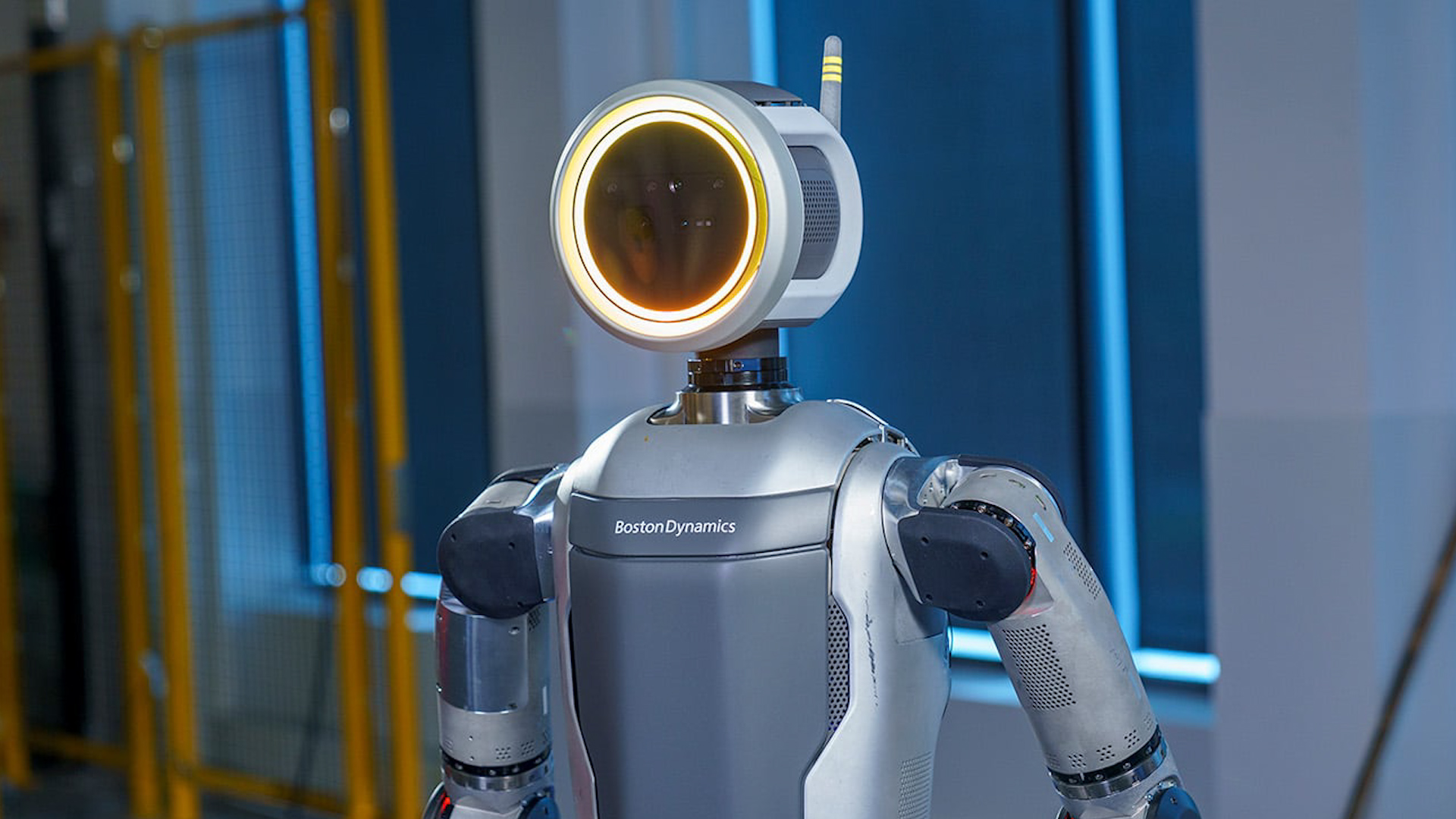

BOSTON DYNAMICS IS SHOWCASING NEW CAPABILITIES IN ITS HUMANOID ROBOT, ATLAS, – NO LONGER NEEDING HUMAN OVERSIGHT. IN VIDEO RELEASED WEDNESDAY – THE ROBOT IS SEEN TAKING ON TASKS AUTONOMOUSLY IN A SIMULATED INDUSTRIAL ENVIRONMENT. ATLAS IS SHOWN MOVING ENGINE PARTS BETWEEN CONTAINERS AND SEQUENCING DOLLIES, RELYING ON ADVANCED MACHINE LEARNING AND SENSORS TO DETECT, GRASP, AND REPOSITION ITEMS.

UNLIKE MANY ROBOTICS DEMOS, ATLAS OPERATES WITHOUT HUMAN OVERSIGHT OR PRE-PROGRAMMED STEPS. BOSTON DYNAMICS SAYS ATLAS DYNAMICALLY RESPONDS TO CHANGES IN ITS SURROUNDINGS — RE-EVALUATING ITS APPROACH IF A PART DOESN’T FIT AS EXPECTED. THIS ADAPTABILITY RELIES ON A COMBINATION OF CAMERA-BASED SENSORS, FORCE SENSORS, AND ADVANCED SOFTWARE, ALLOWING ATLAS TO DETECT, ADJUST, AND REFINE ITS ACTIONS ON THE FLY. THIS LEVEL OF AUTONOMY STANDS IN CONTRAST TO TESLA’S OPTIMUS, WHICH HAS BEEN SHOWN TO RELY ON REMOTE HUMAN OPERATORS FOR CONTROL.

BOSTON DYNAMICS RECENTLY PARTNERED WITH THE TOYOTA RESEARCH INSTITUTE, OR TRI, TO ADD ADVANCED AI TO ITS ATLAS ROBOT. THE COMPANIES SAY THE COLLABORATION IS ABOUT BRINGING TRI’S POWERFUL BEHAVIOR MODELS INTO ATLAS, SO IT CAN ADAPT AND RESPOND QUICKLY TO COMPLEX FACTORY TASKS.

ATLAS’ LATEST MODEL IS NOW FULLY ELECTRIC, DITCHING HYDRAULICS FOR SMOOTHER, MORE PRECISE MOVEMENTS.

BACKED BY HYUNDAI, BOSTON DYNAMICS SEES THIS PARTNERSHIP WITH TRI AS A BIG STEP TOWARD CREATING FLEXIBLE HUMANOID ROBOTS DESIGNED FOR REAL-WORLD WORK. CEO ROBERT PLAYTER SAYS IT’S ALL ABOUT DEVELOPING ROBOTS THAT CAN HANDLE EVERYDAY TASKS IN MANUFACTURING AND BEYOND.

TESLA CEO ELON MUSK PREDICTS THAT BY 2040, THERE WILL BE AT LEAST 10 BILLION HUMANOID ROBOTS PRICED AROUND $20,000 TO $25,000. EXPERTS AGREE ATLAS IS A SIGNIFICANT LEAP, BUT THEY NOTE THAT ITS LONG-TERM SUCCESS WILL DEPEND ON AFFORDABILITY, DURABILITY, AND SCALABILITY FOR WIDESPREAD INDUSTRIAL USE.

FOR MORE OF OUR STRAIGHT FACTS REPORTING, DOWNLOAD THE STRAIGHT ARROW NEWS APP OR VISIT US AT SAN – DOT – COM.