[RYAN ROBERTSON]

THE U-S MILITARY IS AT THE CUTTING EDGE OF MODERNIZATION IN MANY WAYS, BUT IT STILL DEPENDS ON PIECES OF EQUIPMENT THAT ARE MORE THAN A HALF CENTURY OLD…AND THAT’S SIMPLY BECAUSE THOSE PLATFORMS STILL WORK. LONG LIVE THE BUFF (B-52)!

BUT WHEN THOSE SYSTEMS BREAK DOWN AND NEED REPAIR, GETTING THE PARTS CAN BE A PROBLEM.

THE INTRODUCTION OF 3-D PRINTING HELPED, BUT IT’S NOT A CURE-ALL. THE AIR FORCE THINKS IT MAY HAVE FOUND AN ANSWER TO ITS REPLACEMENT PARTS PROBLEM IN A SOUTHERN CALIFORNIA STARTUP.

{MACHINE SOUNDS}

[RYAN ROBERTSON]

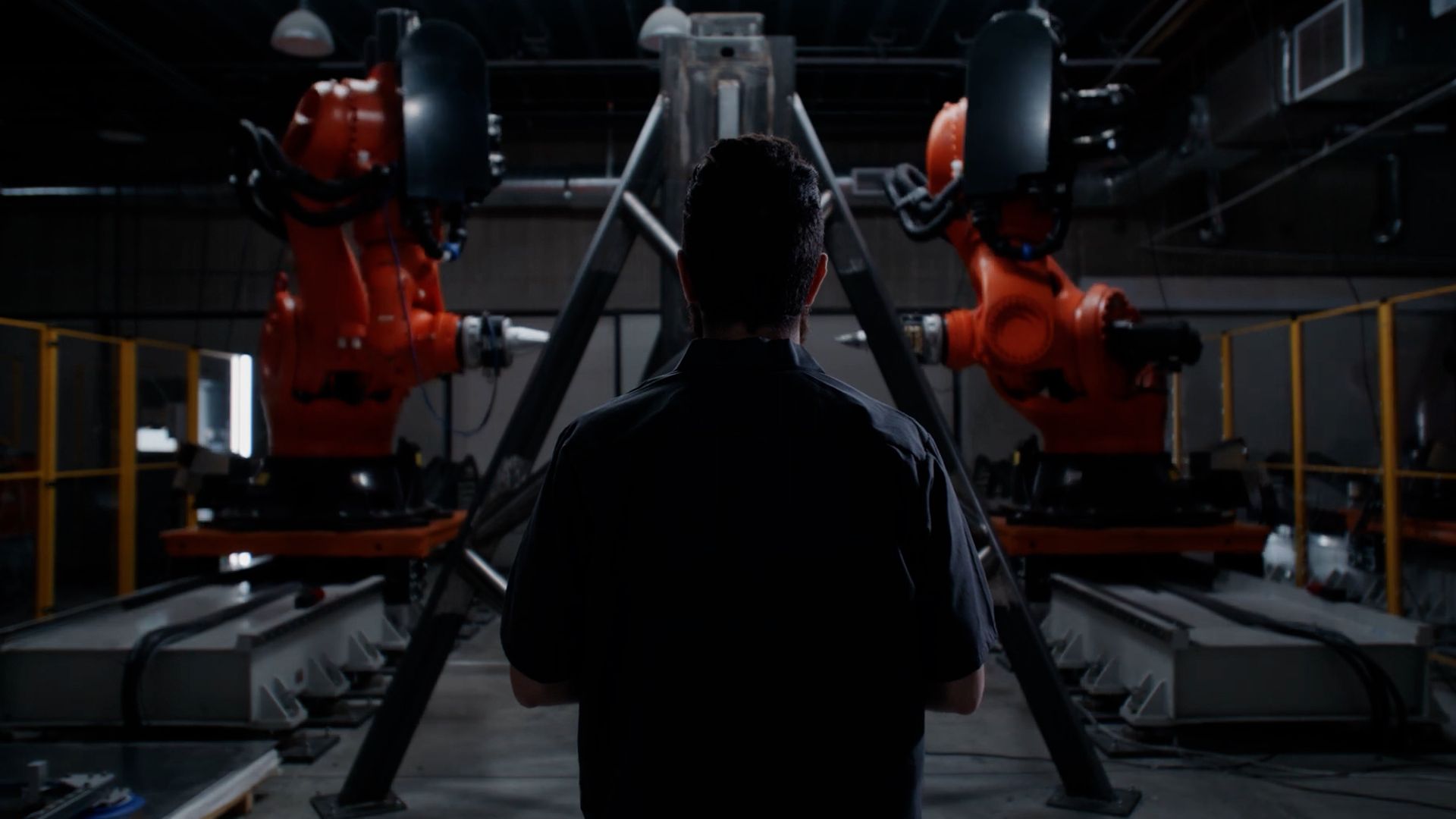

THAT ANSWER IS CALLED THE ROBOTIC CRAFTSMAN, BUILT BY MACHINA LABS. IT’S NOT A 3-D PRINTER…MORE OF A 3-D SHAPER, IT USES ESSENTIALLY ROBOT FINGERS TO FORM PARTS OUT OF SHEET METAL. IT ISN’T LIMITED TO SHAPING JUST ONE KIND OF PART, THOUGHT. THE CRAFTSMAN CAN SHAPE COUNTLESS CONFIGURATIONS. MIKE POLINO, THE VP OF PRODUCT AT MACHINA LABS, SAYS THAT’S A BIG DEAL WHEN YOU’RE TALKING ABOUT SOMETHING A UNIT MAY ONLY NEED ONE OR TWO OF A YEAR.

[MIKE POLINO]

“We call it the robotic craftsman very intentionally. You know, throughout history, metal craftsmen had this like almost unlimited agility, they could pick up a different tool, learn a new craft, and make something new. So maybe a helmet one day, a shield the next day, a tea kettle, the day after that. So in the modern manufacturing context, we needed a lot more scale. So we got rid of all that agility in favor for a fixed tooling that would help us stamp out like many, many, many parts,”

[RYAN ROBERTSON]

FOR THE CREWS RESPONSIBLE FOR MAINTAINING AND REPAIRING THE ENTIRE ARRAY OF VEHICLES AT THE MILITARY’S DISPOSAL THE ROBOTIC CRAFTSMAN CAN BE A GAME-CHANGER. DRASTICALLY REDUCING THE AMOUNT OF TIME ANY GIVEN PLATFORM IS OUT OF SERVICE.

[MIKE POLINO]

“With our system, we’re seeing one-week lead times for parts where previously you might have nine-month 10 Month 12 month lead times for a single sheet metal part to repair or repair an airplane.”

[RYAN ROBERTSON]

THEY KNOW THIS BECAUSE THEY’RE ALREADY SEEING THE RESULTS. IN NOVEMBER OF 2023 MACHINA LABS INSTALLED ONE OF THEIR SYSTEMS AT WARNER ROBINS AIR FORCE BASE IN GEORGIA. ROBINS IS HOME TO THE AIR MATERIEL COMMAND‘S LOGISTICS COMPLEX. THEY PROVIDE EVERYTHING FROM PARTS AND PIECES TO ENGINES AND MISSILES. SO HAVING SOMETHING THAT CAN IN JUST A FEW DAYS REPLACE A PART THAT HASN’T BEEN MADE FOR DECADES IS REVOLUTIONARY.

[MIKE POLINO]

“They’ve been really amazing partners. They’re absolutely leading the charge in new techniques and sustainment. So they’ve helped us collect requirements and been good thought partners and also just generally helped fund some of the R&D which is really important to us.”

[RYAN ROBERTSON]

IF YOU’RE WONDERING HOW IMPORTANT, A REPORT BY DEFENSE ONE SAYS THE AIR FORCE IS ASKING FOR $1.5 BILLION FOR PARTS ALONE IN THE NEXT FISCAL YEAR. ADD TO THAT THE LOOMING THREATS OF RUSSIA AND CHINA AND THE NEED TO GET THIS KIND OF TECHNOLOGY TO CREWS IN THE FIELD BECOMES EVEN MORE IMPORTANT.

[MIKE POLINO]

“Our current version of the system actually folds up into a standard shipping container format, and can be deployed anywhere by rail or by plane. So being forward being in contested environments, being able to inspect and then reproduce parts that maybe go through battle damage is a big part of our mission.”