[JACK AYLMER]

WIND ENERGY IS GETTING EVEN GREENER.

ONCE THE TURBINES ARE UP AND SPINNING, THEY GENERATE ALMOST ZERO POLLUTION.

BUT, BUILDING THEM CAN STILL BE A FAIRLY CARBON INTENSIVE PROCESS.

THE SOLUTION: WOOD.

IT COSTS LESS, IS EASIER TO DISPOSE OF, AND WILL CREATE FEWER EMISSIONS.

THE IDEA IS ALREADY BEING TESTED OUT.

REPLACING THE STEEL TRADITIONALLY USED IN TURBINES COULD MAKE CONSTRUCTING THEM MORE ENVIRONMENTALLY FRIENDLY.

FOR EVERY TON OF STEEL MANUFACTURED, ALMOST TWO TONS OF CARBON DIOXIDE ARE EMITTED.

THE AVERAGE U.S. WIND TURBINE REQUIRES NEARLY 400 TONS OF THIS METAL TO CREATE-

MEANING EACH ONE IS RESPONSIBLE FOR AROUND 800 TONS OF CO2 POLLUTION BEFORE THEY EVEN START PRODUCING ENERGY.

THOSE EMISSIONS ARE EQUIVALENT TO BURNING ALMOST A MILLION POUNDS OF COAL FOR EVERY TURBINE BUILT.

AND THE ENVIRONMENTAL CONCERNS DON’T END ONCE THESE WIND FARMS ARE BUILT.

RETIRING TURBINES IS ALSO A CHALLENGE.

BY 2050, INDUSTRY EXPERTS PREDICT THE WORLD WILL BE DEALING WITH 50 MILLION TONS OF DECOMMISSIONED FIBERGLASS TURBINE BLADES.

-MATERIAL THAT’S NOT EASY TO RECYCLE.

ENERGY COMPANIES IN GERMANY AND SWEDEN ARE PUTTING WOOD TO WORK.

JUST LIKE HOW TREES ABSORB CARBON, THEY’RE PROVING THAT USING WOOD CAN STORE MORE OF THIS POLLUTION THAN THE TURBINES EMIT.

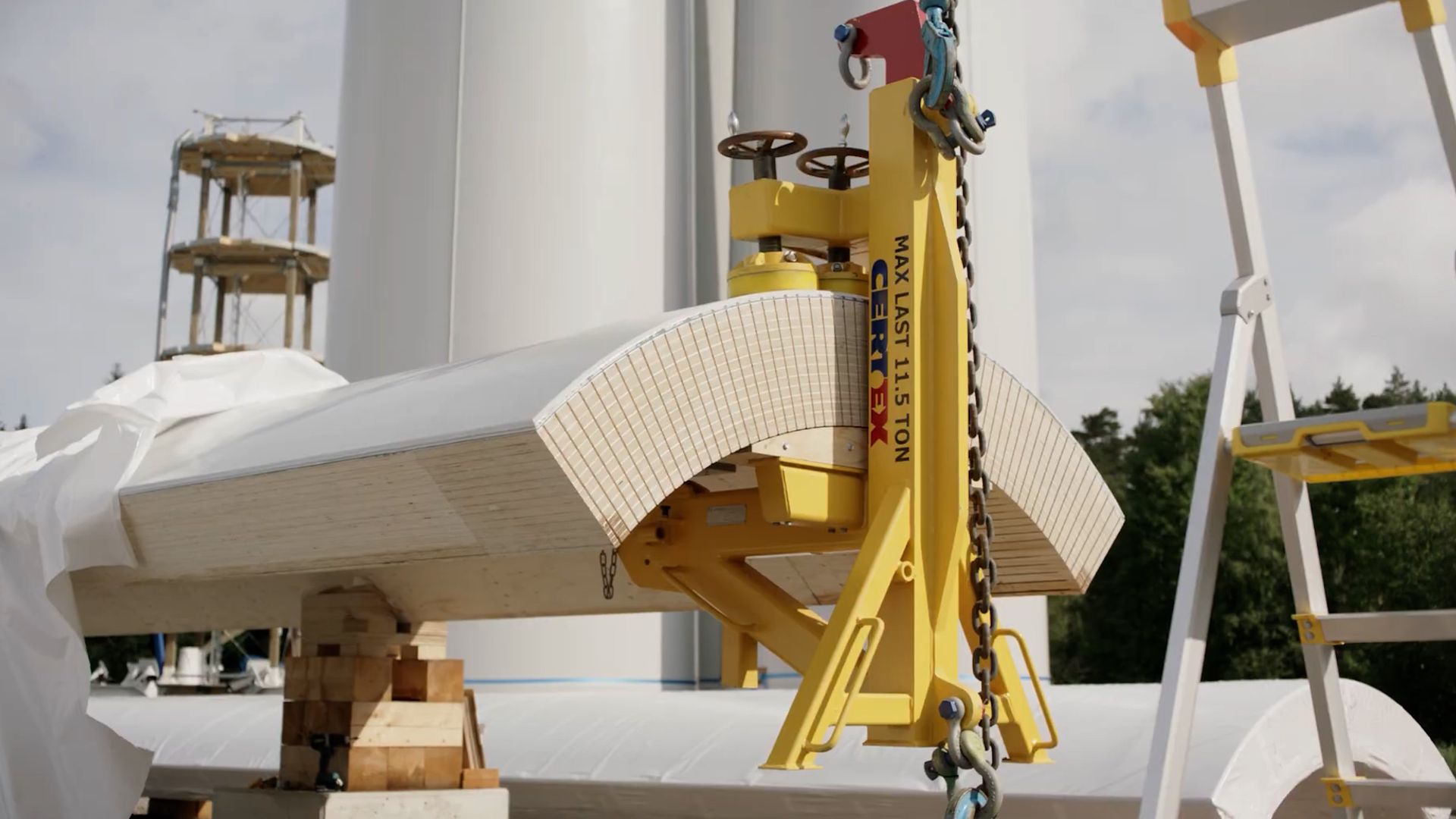

GERMANY recently ANNOUNCED THE FIRST EVER REAL INSTALLATION OF ITS WOOD-BASED BLADES ON A WIND TURBINE AT AN OPERATIONAL FARM.

AND SWEDEN USED SUSTAINABLY MANAGED FORESTS TO BUILD THE WORLD’S TALLEST WOODEN TURBINE TOWER LAST YEAR.

THESE MANUFACTURES SAY THAT USING A WOOD SUBSTITUTE CAN HELP CUT DOWN ON 90 PERCENT OF THE EMISSIONS ASSOCIATED WITH BUILDING A TURBINE.

IT ALSO MAKES THEM MUCH EASIER TO RECYCLE, WITH SOME OF THE WOODEN BLADES BEING COMPLETELY BIODEGRADABLE.

ALL WHILE CUTTING COSTS ON BUILDING MATERIALS BY UP TO 20 PERCENT.

BENEFITS THAT WILL BE MUCH NEEDED AS WIND ENERGY IS SET TO GROW EXPONENTIALLY OVER THE NEXT THREE DECADES.

MORE THAN A THIRD OF THE U.S. AND HALF OF EUROPE ARE EXPECTED TO BE POWERED BY TURBINES COME 2050.

JACK AYLMER – STRAIGHT ARROW NEWS.